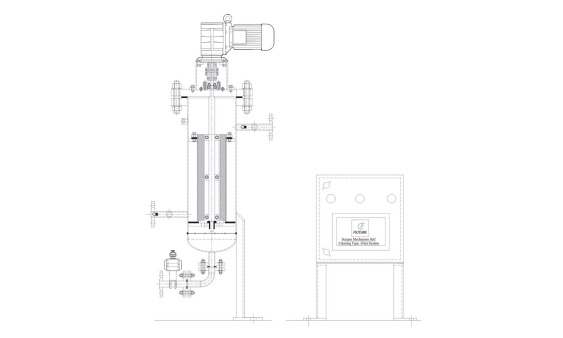

Self Cleaning Filter

Self Cleaning Filters assure continuous flow, trouble-free operation and simplified maintenance. Scrapper Mechanism Self Cleaning is used for preliminary filtration following the same principle of differential pressure. It is easy to clean element just by rotating knob or outside shaft handle manually or by a geared motor. The contaminant from the element surface are by a Brush or Scraper Blade and collected at the bottom can be drained out easily.

Self cleaning filter working principle

The medium to be cleaned is guided into the filter by inlet, which passes from inside to outside through the element gap. After filtration, the filtered fluid enters the filter housing from the to. The bigger solids are separated on the inner surfase or filter element. When it runs for a certain time, the gap between wires element gets plugged up by impurities and meanwhile the differential pressure reaches its pre-set value. Then PLC inspects the signal and sends out the indication to gear motor. The gear motor drives the scraper and the particles or agglomerates are skimmed from the surface, thereby keeping the function of elements well and keeping the element gap clean.

When the impurities at the bottom of the filter increases, the drain valve opens up and the impurities are emptied successfully, which makes the system pressure achieve normality. Because of well-set position and optimum scraping angle, the a rotational scraper drains off the impurities from the filter with the help of the gear motor. This avoids the burden of taking apart the element and washing it, which results into successful filtration of the medium. The scraper system contains Agitator, Mechanical Seal and Control Panel, which are designed for automatic cleaning, and especially for the reasonable spring pressure, maximally reducing the element's abrasion.

The medium to be cleaned is guided into the filter by inlet, which passes from inside to outside through the cartridge gap. After filtration, the filtered fluid exits the filter housing from the top, opposite to the inlet connection and the bigger solids are separated on the surface of the triangular cartridge wires. When it runs for a certain time, the cartridge gap gets plugged up by impurities and meanwhile the differential pressure reaches its pre-set value. Then PLC inspects the signal and sends out the indication. The gear motor drives the scraper and the particles or agglomerates are skimmed from the surface, thereby keeping the function of cartridge well and keeping the cartridge gap clean.

When the impurities at the bottom of the filter increases, the drain valve opens up and the impurities are emptied successfully, which makes the system pressure achieve normality. Because of well-set position and optimum scraping angle, the rotational scraper drains off the impurities from the filter with the help of the gear motor. This avoids the burden of taking apart the cartridge and washing it, which results into successful filtration of the medium. The scraper system contains stator, PTFE scraper and spring, which are designed for automatic cleaning, and especially for the reasonable spring pressure, maximally reducing the cartridge's abrasion.

SingleBag Filter system suitable for

- Compact Design and Low in weight

- Low pressure drop across the filter

- Adequate strength of element and housing

- Filter element with very high mechanical strength

- Low Maintenance Cost

- Component or parts suitable for and compatible with hydraulic fluid concerned.

- Allow to interchange same type of component with another

- Filtration down to 40 microns

- Highly affordable, long-lasting equipment, with low operation costs

- Petrochemical Plants

- Chemical Plants

- Power Plants

- Pulp industries

- Nuclear Plants

- Process Water

- Paper Plants

- Steel Plants

- Mines

- Effluent treatment

- Cooling Towers

- Paints and pigments

- Irrigation

- Water treatment